Page 29 of 30

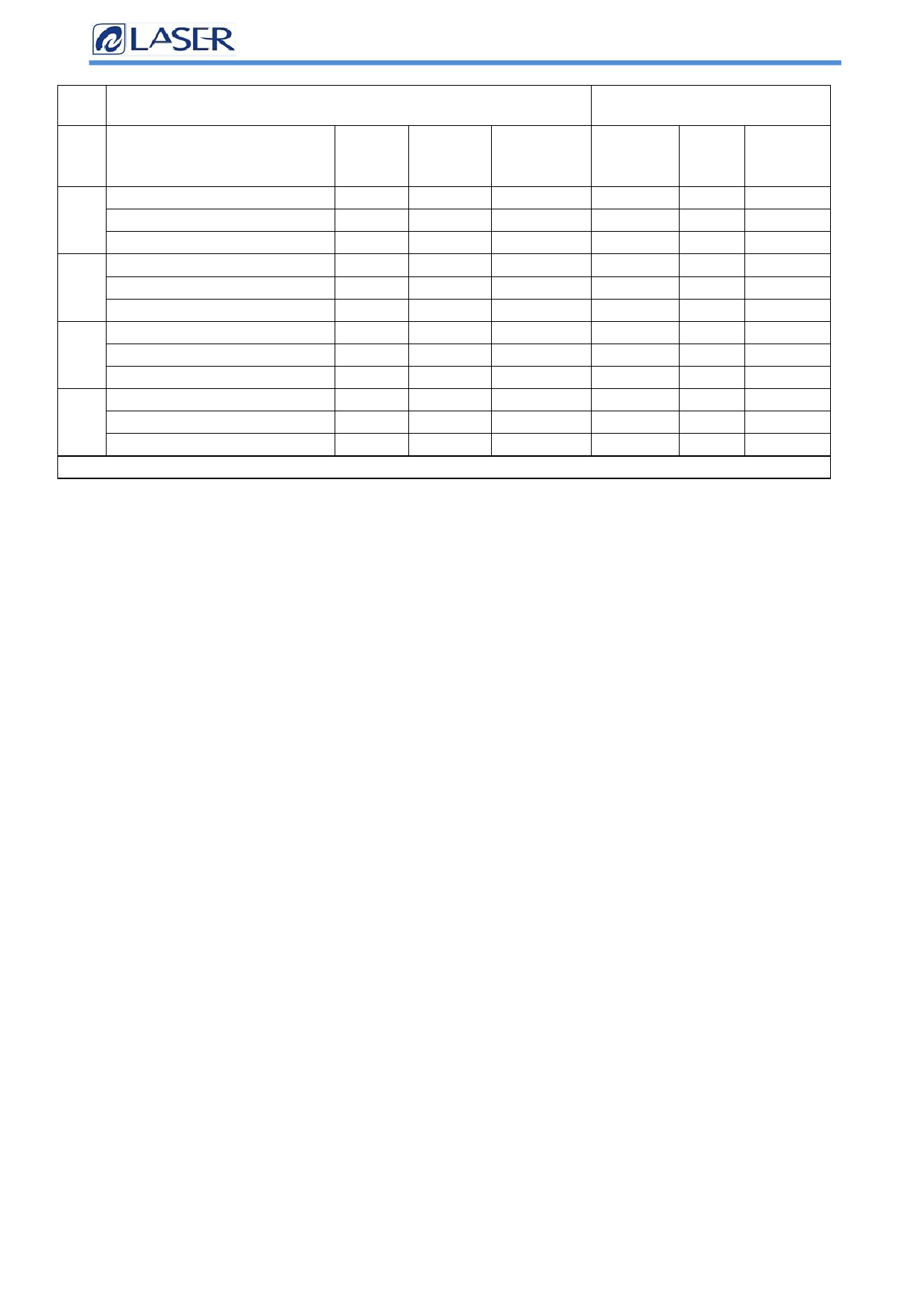

BWT20 Qilin Wobble Handheld Laser Welding Head

1500W Laser control

Laser head control

No. Material and thickness Power Freq.

Duty

cycle

Pattern Freq. Width

Stainless steel 1.0

30% 3000Hz 100%

○

10hz 1.6mm

1

Stainless steel 2.0

60% 3000Hz 100%

△

10hz 2.6mm

Stainless steel 3.0

90% 3000Hz 100%

⨝

10hz 3mm

Carbon steel 1.0

30% 3000Hz 100%

○

10hz 1.6mm

2

Carbon steel 2.0

60% 3000Hz 100%

△

10hz 2.6mm

Carbon steel 3.0

85% 3000Hz 100%

⨝

10hz 3mm

Galvanized plate 1.0

35% 3000Hz 100%

○

16hz 1.6mm

3

Galvanized plate 2.0

65% 3000Hz 100%

△

16hz 2.6mm

Galvanized plate 3.0

85% 3000Hz 100%

⨝

16hz 3mm

Aluminum plate 1.0

40% 3000Hz 100%

○

10hz 1.6mm

4

Aluminum board 2.0

70% 3000Hz 100%

△

8hz 2.6mm

Aluminum plate 3.0

85% 3000Hz 100%

⨝

8hz 3mm

The above parameters are provided for reference only

Precautions for using a laser welding system

1. Laser welding machine includes laser source, chiller, laser welding system, laser welding

head multiple control modules. In order to avoid interference, to ensure that the argon

arc welding machine and related equipment with large interference, to ensure a safe

distance of more than 5 meters.Ensure that the laser welding machine has independent

space when conditions permit.

2. In order to reduce the equipment leakage or static electricity, to ensure that the light

double pendulum industrial welding head equipment uses effective ground wire.

3. Please repeatedly confirm whether the sleeve joint is normally connected and locked,

which can be wrapped with insulation tape.

4. Check whether the laser head and the optical fiber are locked and connected. After

confirming the normal condition, use the tape tape to ensure that the dust does not

enter the laser head cavity.

5. Check whether there is water seepage in the cavity. There are many waterways in the

cavity. The screws should not be loosened without professional training to prevent water

droplets from entering the cavity.

6. Check whether the protective lens drawer is normal, ensure that the sealing ring is

normal and effective, ensure that the protective lens wipes the external stains of the

laser lens, at least 5 times, and ensure that the lens environment is dust and wind.

7. The laser head is complex. To avoid short circuit, stay away from the water source and

ensure that no liquid can be sprayed on the laser head.

8. Laser head refuse to use strong wind to blow and clean the laser head, can only use

alcohol and dust-free cloth to wipe.

9. A digital motor is installed inside the laser head, which must be taken and put gently

Shenzhen Qilin Laser Application Technology Co., Ltd.