- interface

with driver PUL-

Motor wire feed

Used for motor wire feed and connection

3

DIR+

direction + interface with driver PUL+

Motor wire feed

Used for motor wire feed and connection

4

DIR-

direction - interface with driver Dir

5

GND

Reference ground

—

Wire feed control

Used for automatic wire feed of IO control

6

Feed

interface

wire feeder

Wire drawing control Used for automatic wire feed of IO control

7

Backoff

interface

wire drawing

8

OVCC +24V power output Power supply, maximum output is 500mA

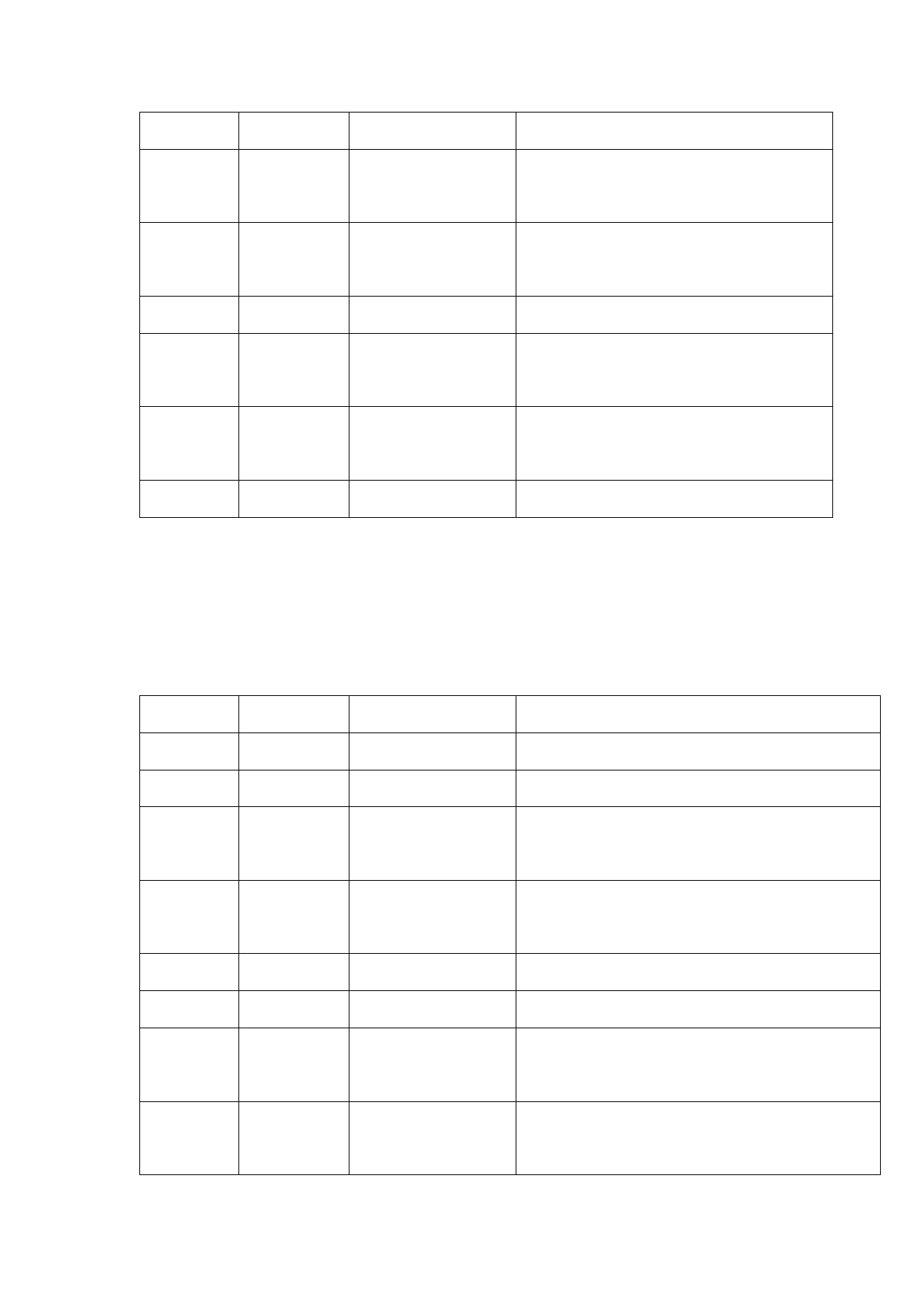

6.5 CN2 laser interface

The laser interface is a 8PIN green terminal. Table 6.5.1 shows the

definition of laser interface.

Table 6.5.1

Pin

Signal

Definition

Description

1

PWM+ Modulating signal+ Duty ratio: 1%-99% (adjustable), 24V level

2

PWM-

Modulating signal-

Duty ratio: 1%-99% (adjustable), 24V level

0-10V analog voltage, used for laser peak power

3

DA

Analog voltage output

adjustment

Power reference

Generally connecting to DA- and Enable-end

4

GND

ground

5

OVCC +24V power output Power supply, maximum output is 500mA

6

Enable Laser enabling signal 24V level and high level: effective

Laser failure alarm

—

7

Alarm

input

The signal is needed by part of lasers. The function

8

GATE

Red light index signal

is reserved for use when leaving the factory

20