For example

If you are running at 18000 RPM using a 25mm cutter with two flutes, and a recommended chip load

of 0.1 mm/tooth:

Feed = 2 x 0.1 x 18000 = 3600 mm per min

Chip load is specific to the router bits hence one has to check the data sheet of the bits in question to

come up with the right value to use for the calculations.

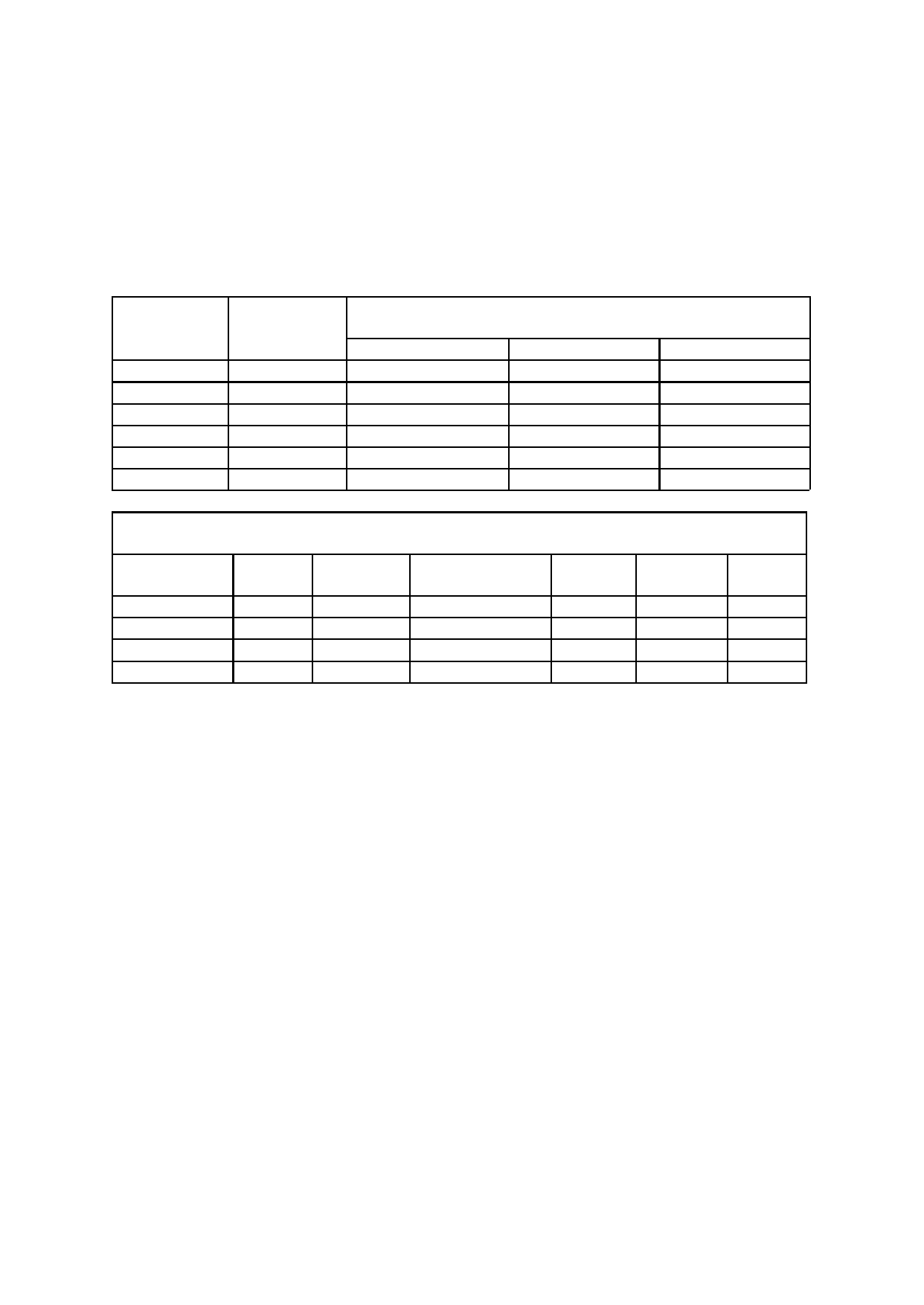

Suggested Feed rates

No of cutting Chip Thickness

Feed rate (mm/min)

edges (Z)

(mm)

at RPM

18000

21000

24000

1

0.1

1800

2100

2400

2

0.1

3600

4200

4800

3

0.1

5400

6300

7200

1

0.4

7200

8400

9600

2

0.4

14400

16800

19200

3

0.4

21600

25200

28800

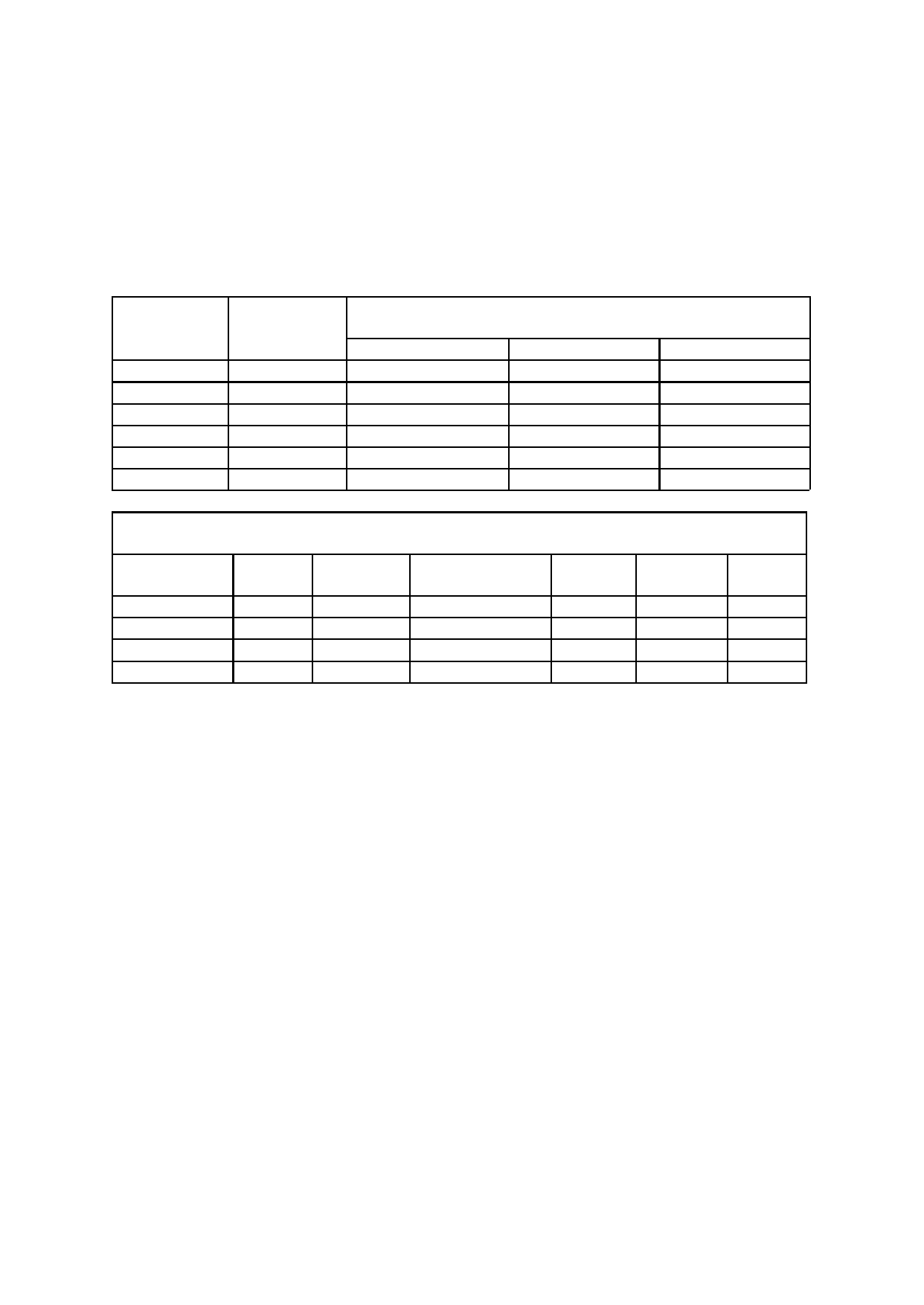

Typical chip thickness values for various size cutters

Cutter Diameter Hardwood Softwood/Ply MDF/Particleboard Soft Plastic Hard Plastic Aluminium

3mm

6mm

10mm

12mm and over

.08 -.13

.23 - .28

.38 - .46

.48 - .53

.1 - .15

.28 - .33

.43 - .51

.53 - .58

.1 - .18

.33 - .41

.51 - .58

.64 - .69

.1 - .15

.2 - .3

.2 - .3

.25 - .36

.15 - .2

.25 - .3

.25 - .3

.3 - .41

.05 - .1

.08 - .15

.1 - .2

.2 - .25

Factors to consider for good and efficient practice.

For hard material, use lower chipload than the design value. For soft material you can use a higher

value.

A flute is designed to cut the same depth as the diameter of the tool, which means a 6mm tool should

step down 6mm. The chip rate is designed according to that value.

You should take into consideration that if you go deeper, clearly more force will be applied on the tool,

which means the tool will require more torque, making it more susceptible to snapping.

A rule of thumb is, if you step down twice, use 2/3 of the speed, if you step down 3 times, use 1/2 of

the speed. It is advisable not to go any further otherwise the bit may snap.

NB this step down is not calculated from the surface of the material, rather from thickness remaining

after each cut(pass).

This lead to another question, if I want to cut a board 20mm thick, can I use a 6mm tool with flute

length only 6mm or 20mm+, answer is 20mm plus (thicker than the board), but you

may ask, if I only step down 6mm each time, then the rest of the flute is a waste which only increases

manufacture cost and decrease the strength, In theory yes, but in reality, each pass has tolerance,

maybe 0.01mm difference from the previous pass or more, then with a flute, it will cut, otherwise a

solid rod will increase chance of snapping.

A good combination of feedrate(mm/min), spindle speed RPM, step down(mm) and tool itself can

result in a clear cut, too fast will cause a waved edge, too slow will cause a rough edge.

KB Article by Takura Mutami