Chapter 9 Return to Mechanical Origin

Chapter 9 Return to Mechanical Origin

“Mechanical Origin” is a fixed position in the machine tool. It is the zero position of

the mechanical coordinate system and determined by the mechanical switch and

electrical system together. To execute the “Return to Mechanical Origin” function,

the machine tool itself needs to be installed the origin switch. If it doesn't have the

related hardware support, this function shall be prohibited. See the origin parameter

setting in Chapter 11 Parameter Management. As mechanical origin is the basic

standard of the whole machine tool, thus its main function is to revise the present

coordinate. Please execute Return to Mechanical Origin when system starts or stops

urgently in order to prevent from power off or wrong current position.

When the system starts, the dialogue box “Return to Mechanical Origin” will

automatically pop up. Click the button, the corresponding axes will go back to the

mechanical origin automatically and revise the coordinate of the system. Before the

X/Y axes go back to the origin, please make sure that the Z axis will go back to the

mechanical origin first.

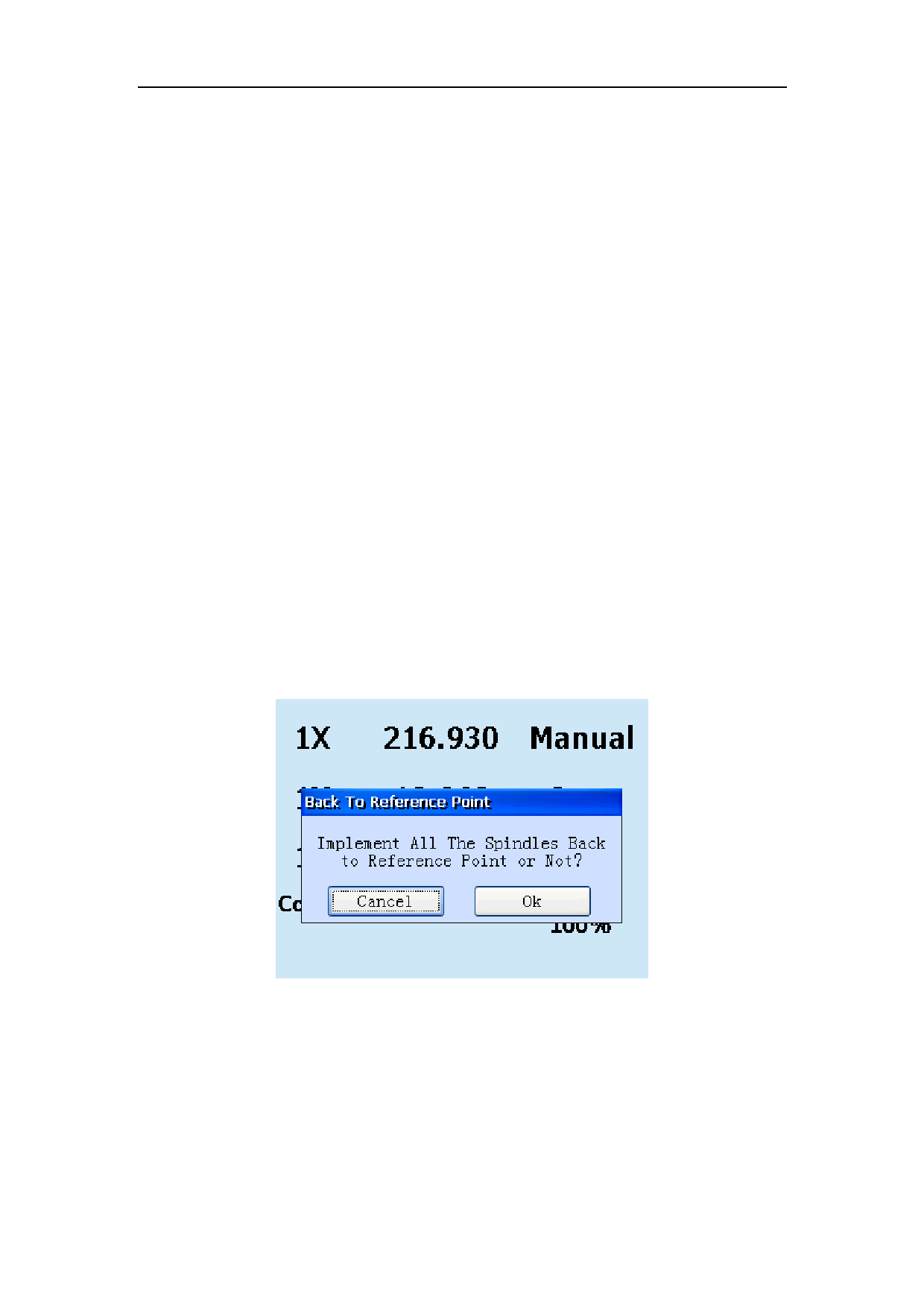

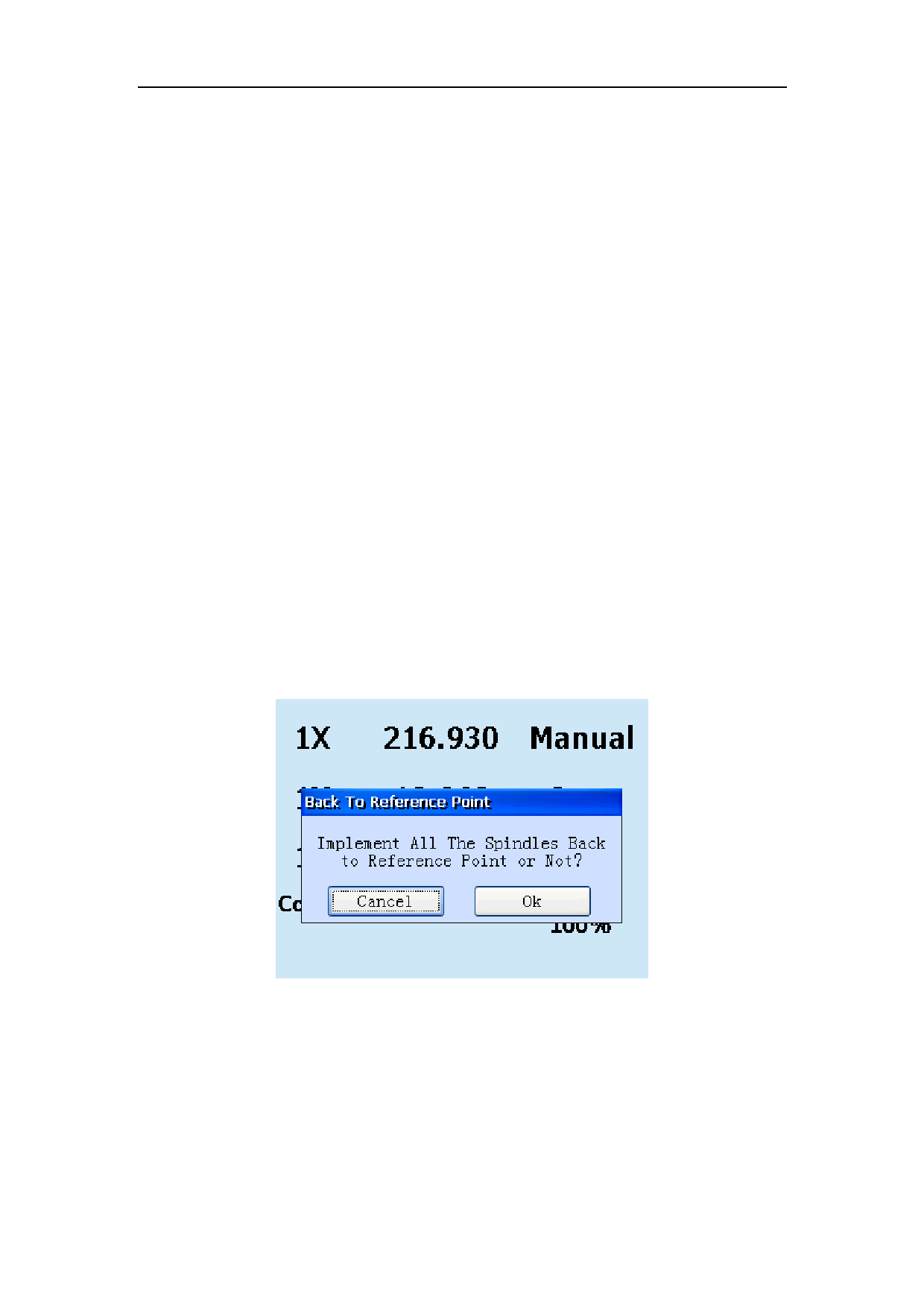

Select the item “Return to Mechanical Origin”; the system will pop up the dialogue

box “Return to Mechanical Origin”. See the figure below:

Fig 9-1 Prompt Information of Backing to Reference Point

Sequence of all axes going back to mechanical origin:

Firstly, Z axis return to mechanical origin, and it should stop right now when meeting

the hardware limit during the process of returning to origin. After Z axis finding

origin, please clear Z axis workpiece coordinate. In the following, X, Y axes will

27