Chapter 5 How to Setup Workpiece Origin

① T

o

To the surface of

feeler block t

h

e

Workpiece s工ur件fac表e面

s

u

Feel对er刀B块rlock

f

a

c

e

Top

Record workpiece of current point

in Z direction

②Raise 10mm

Surface

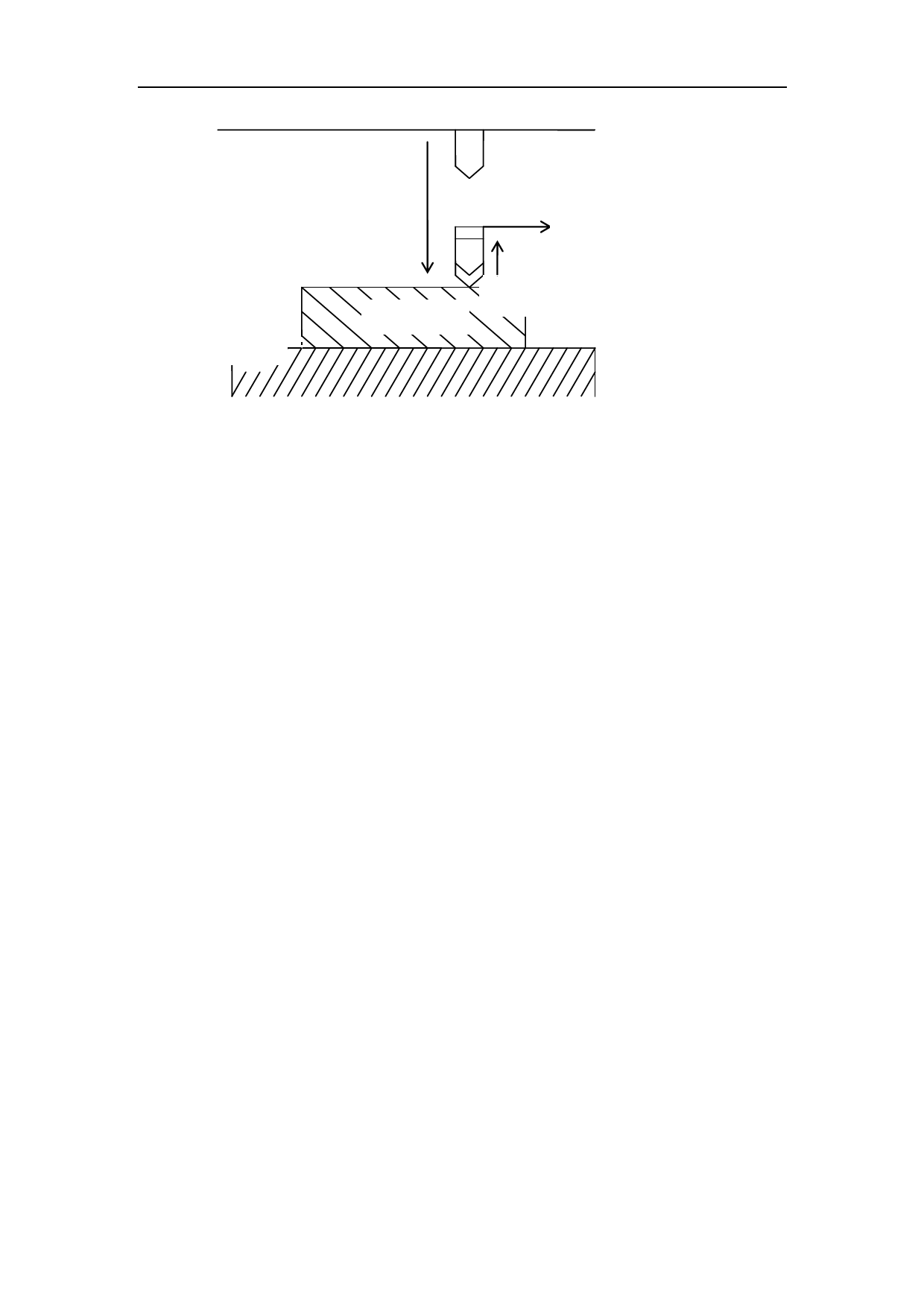

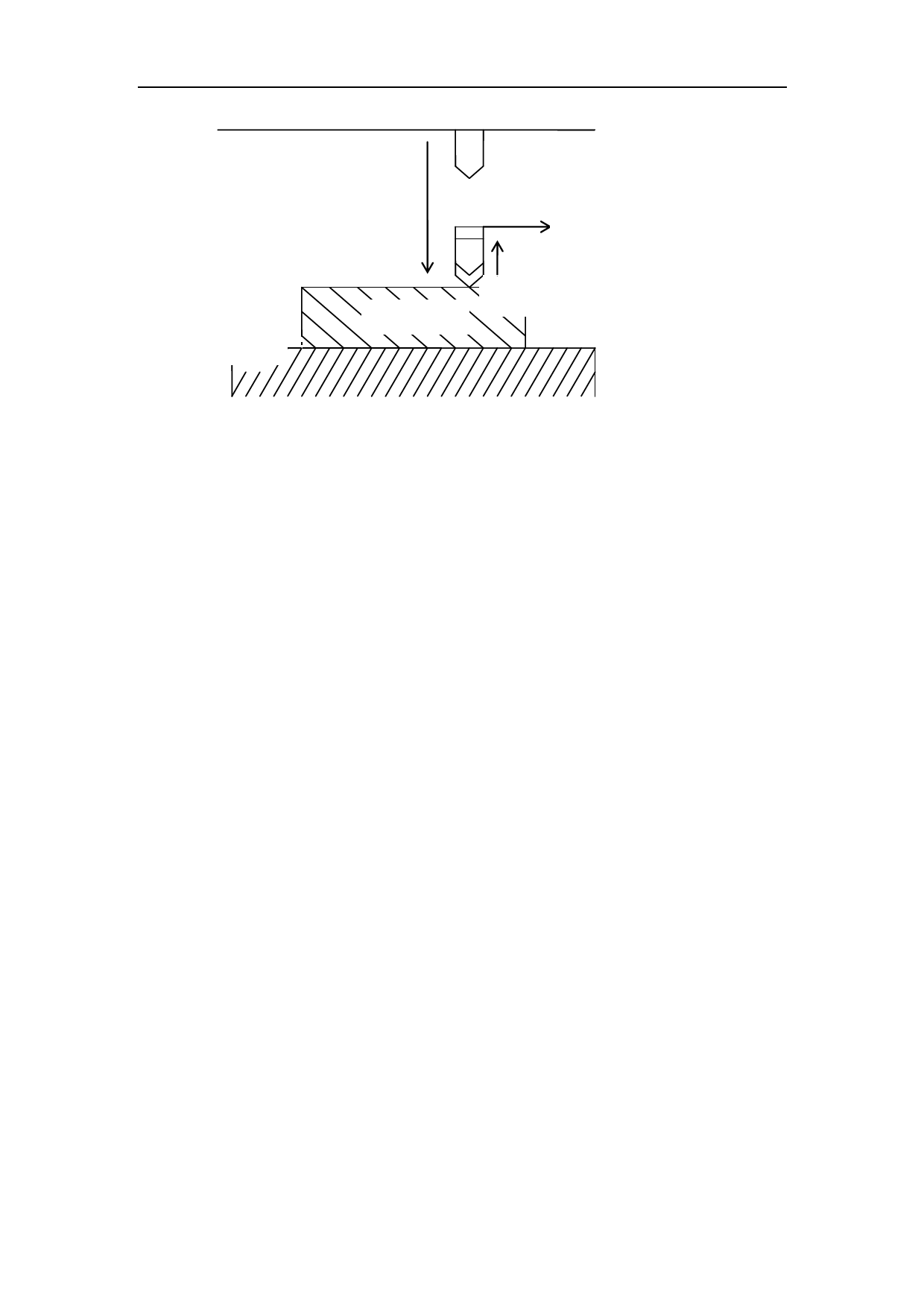

Fig 5-2 Diagramo of Floating Tool Setting

f

f

Note:

e

e

(1) Before tool setting, operators havle to make sure that the tool nose is above the

e

feeler block, which means that the toorl nose shall touch the feeler block when feeding

the cutter, otherwise the cutter head abnd workpiece will be damaged as the machine

l

tool keeps on feeding.

o

c

(2) The thickness of the feeler blockk can be set in “Factory Parameter”. The

workpiece origin coordinate in Z axis will compensate the thickness after setting the

tool.

(3) The speed of tool setting, ranging from 60 to 1000 mm/min, can be set in

“Parameter Setting”. If the speed is over the maximum of the set parameter, then the

cutter head or feeler block will be worn-out.

16