Chapter 5 How to Setup Workpiece Origin

Chapter 5 How to Setup Workpiece Origin

Before machining the files, operators can adjust the position of the tools and

workpieces manually so that the machine can work at the preset position of the

workpiece.

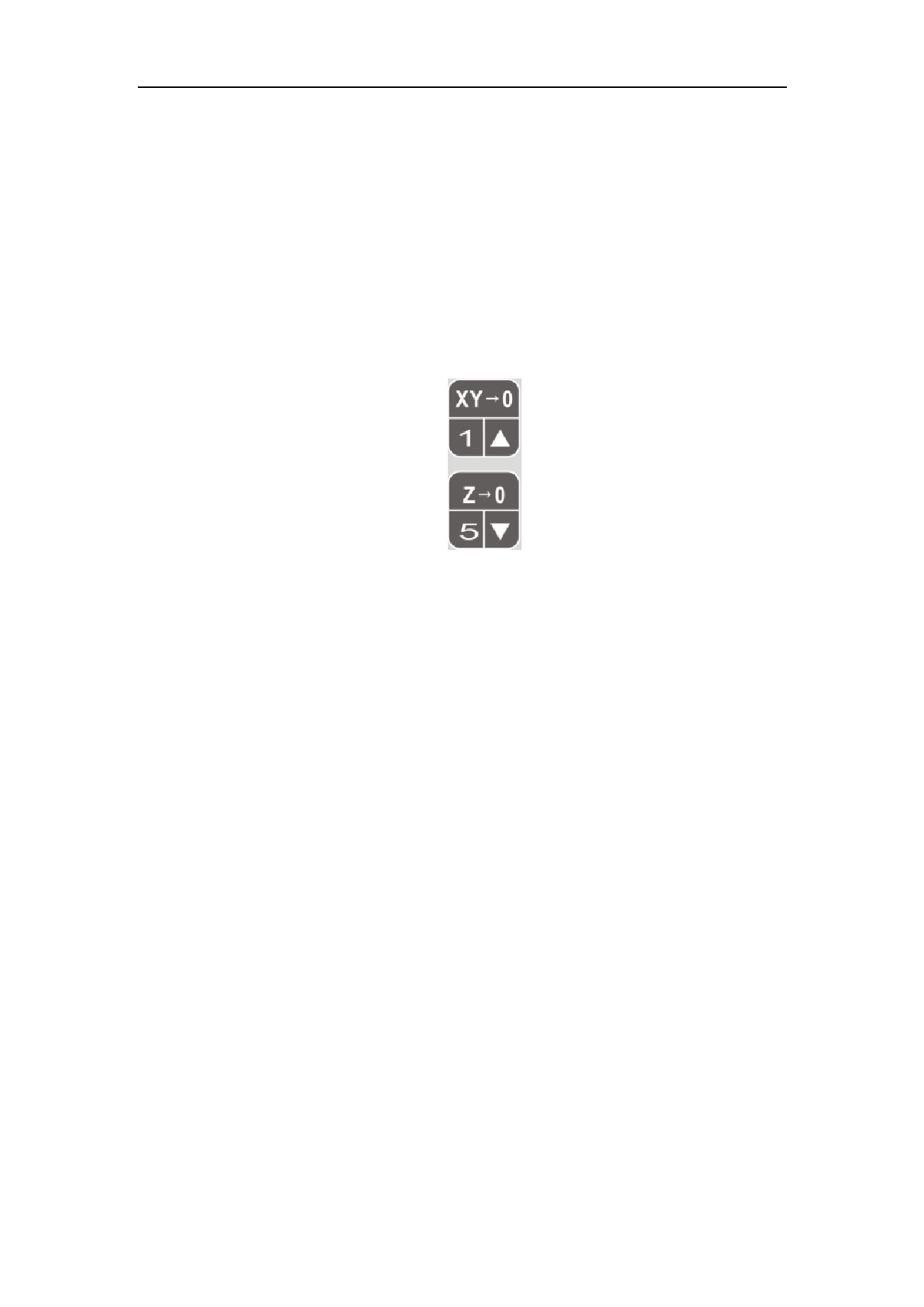

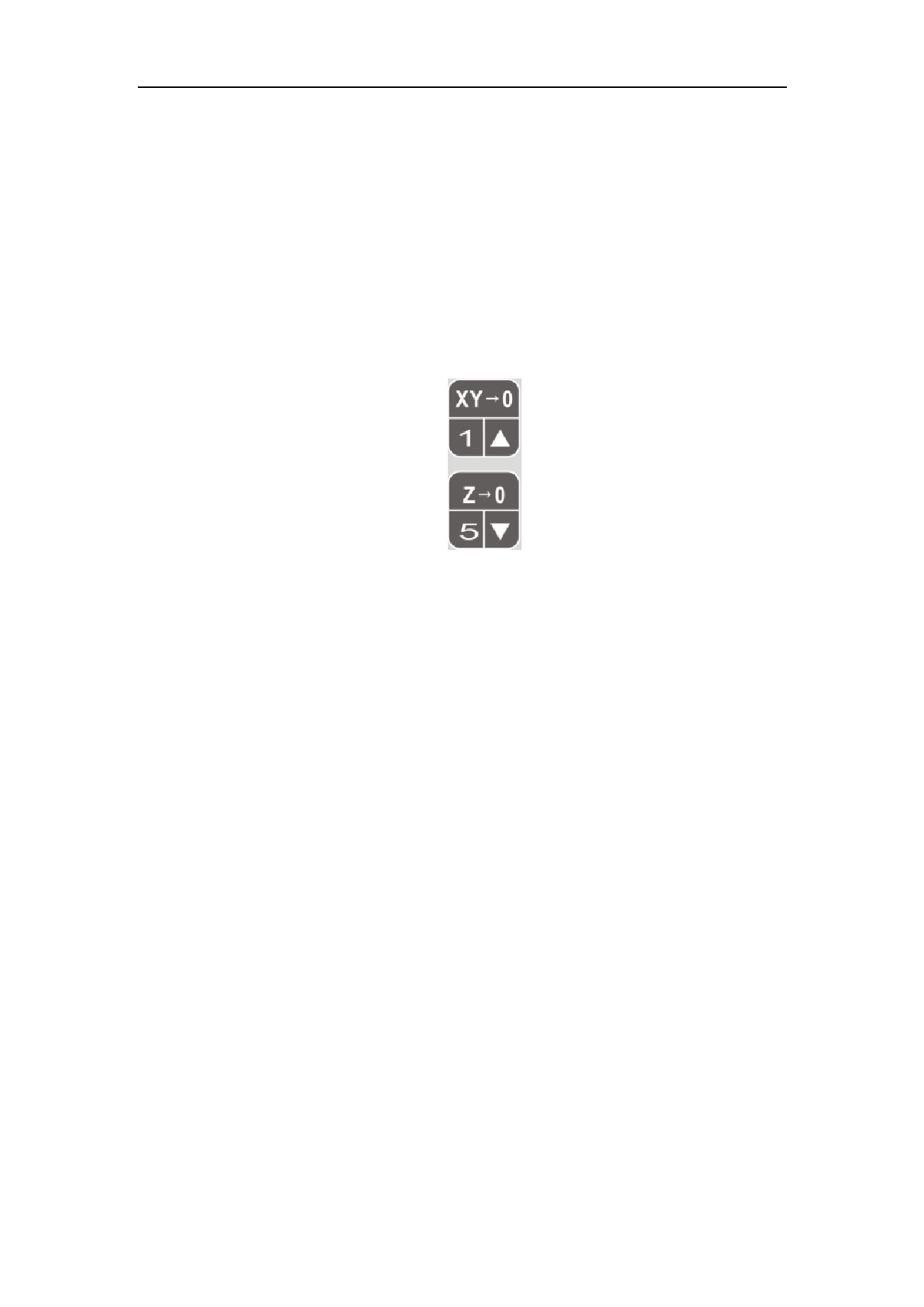

Workpiece origin of X/Y axes setting: run the X/Y axes to the preset position

manually and press the button “xy->/1” to clear the coordinate value of X/Y axes at

current position. The figure below is the button area of workpiece origin setting:

Figure 5-1 Workpiece Origin Setting

There are two ways to set up the workpiece origin of Z axis, i.e., Manual Setting,

Floating Tool Setting.

1. Manual Setting is similar to the X/Y workpiece origin setting.

2. Floating Tool Setting makes it convenient for operators to locate the height of the

workpiece surface and set the workpiece origin of Z axis. Specific operations are as

follows: Put the feeler block on the surface of the workpiece and move the tool nose

above the workpiece origin through manual operation. Then press the combined key

“Shift” + “Z-“, the system will pop up a dialogue box, inquiring if the position of the

tool setting is right. Then click “OK”. When the machine tool is performing the tool

setting operation, the tool nose will touch the feeler block and then it will raise 10 mm

by itself. Together with the thickness of the feeler block, the coordinate of the Z axis

will be identified.

15