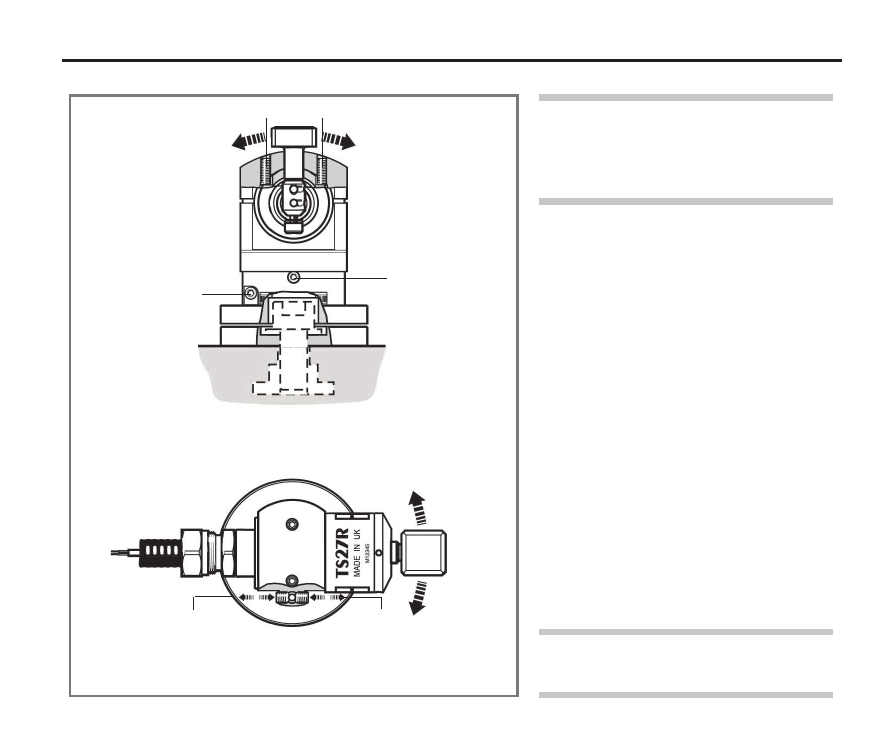

Square stylus alignment

19

L3

L3 and L4

level

side to side

2.5 mm A/F

0.7 Nm – 0.9 Nm

(0.52 lbf.ft – 0.66 lbf.ft)

R2 and R3

L4

A

2 mm A/F

1.0 Nm – 1.2 Nm

(0.74 lbf.ft – 0.89 lbf.ft)

coarse rotational

adjustment

for square styli

R1

2.5 mm A/F

0.7 Nm – 0.9 Nm

(0.52 lbf.ft –

0.66 lbf.ft)

Fine rotational

adjustment

for square styli

R2

2.5 mm A/F

0.7 Nm – 0.9 Nm

(0.52 lbf.ft – 0.66 lbf.ft)

R3

2.5 mm A/F

0.7 Nm – 0.9 Nm

(0.52 lbf.ft – 0.66 lbf.ft)

CAUTION: Always hold the support bar

in position to counteract twisting forces

and avoid over-stressing the stylus

break stem.

Additional setting for square styli

Stylus level setting is the same for disc

and square styli. In addition, square

styli side faces can be aligned with the

machine’s X/Y axes.

Coarse rotational adjustment is

obtained by slackening the stylus holder

grubscrew A (see page 16), rotating

the stylus in its holder, then retightening

grubscrew A. (Always use the support

bar – see page 17.)

Fine rotational adjustment is obtained

by loosening the four grubscrews R1

and alternately adjusting the two probe

rotational adjuster screws R2 and R3

until the required tip parallelism to the

axes is achieved. Retighten grubscrews

R1, R2 and R3.

CAUTION: Ensure all screws are tight

after adjustment.