- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- KR Inverter ACD320 Series Manual.pdf

- Page 117 of 160

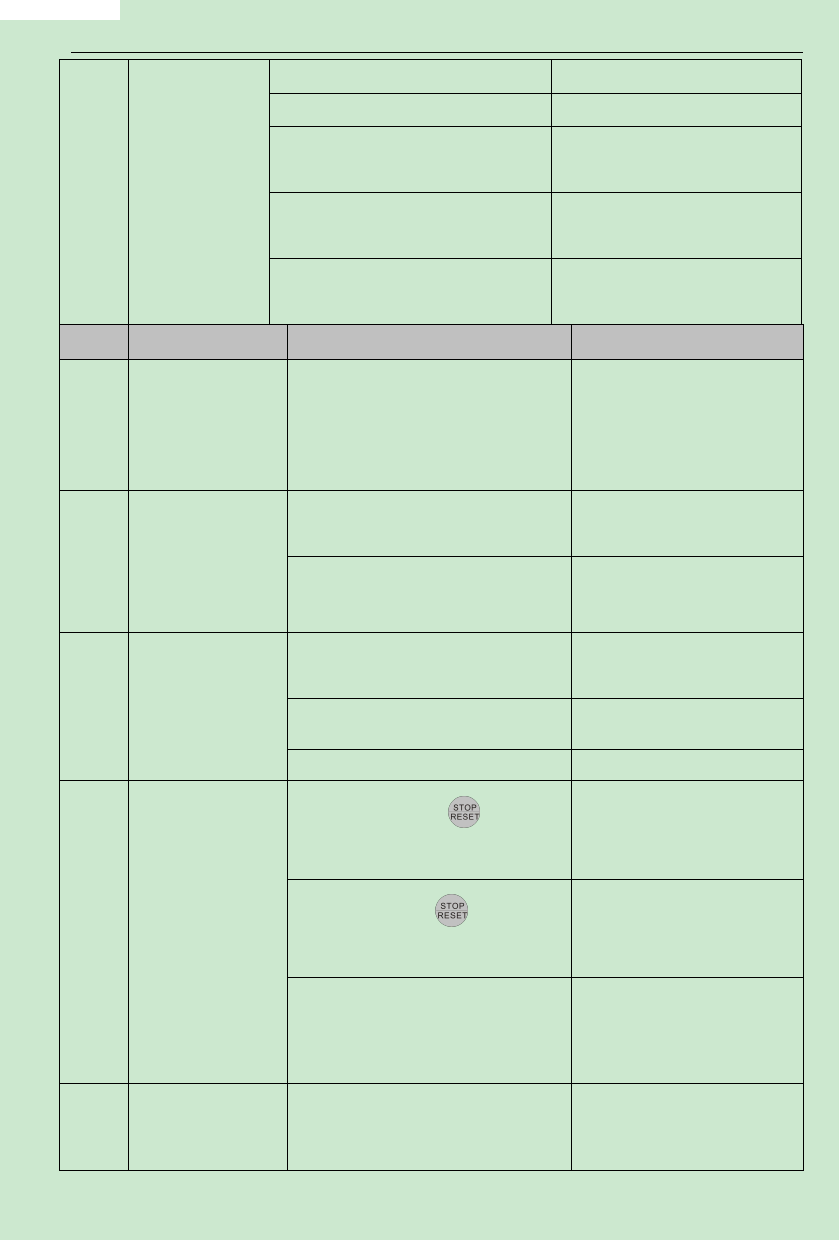

ACD320user manual

Fault Diagnosis and countermeasures

U-11

Motor overload

Improper V/F curve

power source voltage is too low

General motor run at low speed with big

load

motor overload protection factor set

incorrectly

Adjust V/F curve and torque boost

check power source voltage

Can choose frequency conversion

motor for long time low speed run

to set motor overload protection

factor correctly

failure

code

failure type

motor blocked up or load change too

suddenly and quickly

possible reason

U-12 Missing input phase Three-phase input power is abnormal

Reduce the load and check the

motor and

countermeasure

Check and remove the problems

in the peripheral lines,To make

the three-phase power entering

the frequency inverter normal

U-13

U-14

Missing output phase

The lead wire from inverter to the motor

is abnormal.

Check if the three-phase output of

frequency inverter is balanced when

running without motor

Air-path blocked

inverter over heating Ambient temperature is too high

Fan damaged

Remove peripheral fault.

Check if the motor three-phase

winding is normal, If no, remove

the fault.

To clear air-path or improve

ventilation condition

Improve ventilation condition,

lower carrier frequency

Replace the fan

use sudden stop key in

run mode

non-keypad Reset running

U-15

external device

failure

Use sudden stop key

condition of stall

under

Set running parameter correctly

Sudden stop terminal MI for external

failure closed

Open external failure terminal

after external failure is settled

U-16

RS485

communication

failure

Baud rate set improperly

- 112-

set Baud rate properly