- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- KR Inverter ACD320 Series Manual.pdf

- Page 116 of 160

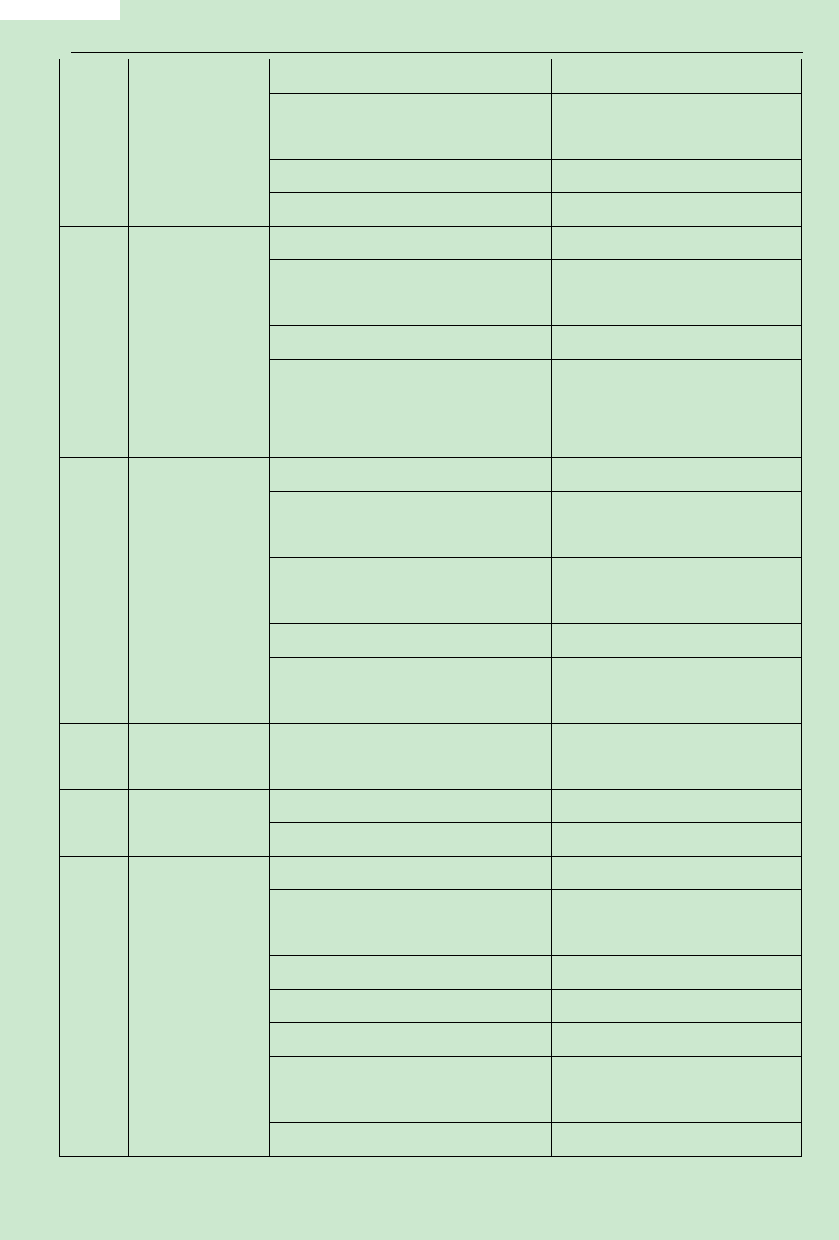

ACD320user manual

Fault Diagnosis and countermeasures

U-05

overvoltage during

accelerating

process

input voltage is a bitter high

There is external force driving the motor

in accelerating process.

Accel time is set to too short

Check input power supply

Cancel this force or addbraking

resistor

Prolong accelerating time properly

Restart rotating motor

Set to be speed tracking starting

Input voltage is too high

Check input power supply

U-06

Overvoltage

during

decelerating

process

There is external force driving the motor

in decelerating process.

Decelerating time is too short

Have potential energy load or big inertia

load

Input voltage is too high

Cancel this force or addbraking

resistor

Prolong decelerating time

Increase braking power of external

energy consumption braking

subassembly

Check input power supply

U-07

Overvoltage

during constant

speed process

There is external force driving the motor

in operating process.

Accel/Decel time is set to too short

Input voltage change abnormally

Cancel this force or addbraking

resistor

Prolong accelerating decelerating

time properly

Assemble reactor

Load inertia is a bit big

Use energy consumption

subassembly

U-08

U-09

Control power

failure

Unwonted input voltage

Under voltage

failure

transient power off

Input voltage is too low

Check input power supply or look

for service

Reset falure.

Check input power supply

Accel time is too short

Prolong accelerating time

DC injection braking is too big

Reduce DC injection braking

current.prolong braking time

Improper V/F curve

Adjust V/F curve and torque boost

U-10

Inverter overload

Restart rotating motor

power source voltage is too low

Set to be speed tracking starting

check power source voltage

Load is too big or motor is blocked.

Reduce the load and check the

motor and macine.

Power of inverter is a bit small

Choose inverter with high-power

- 111-