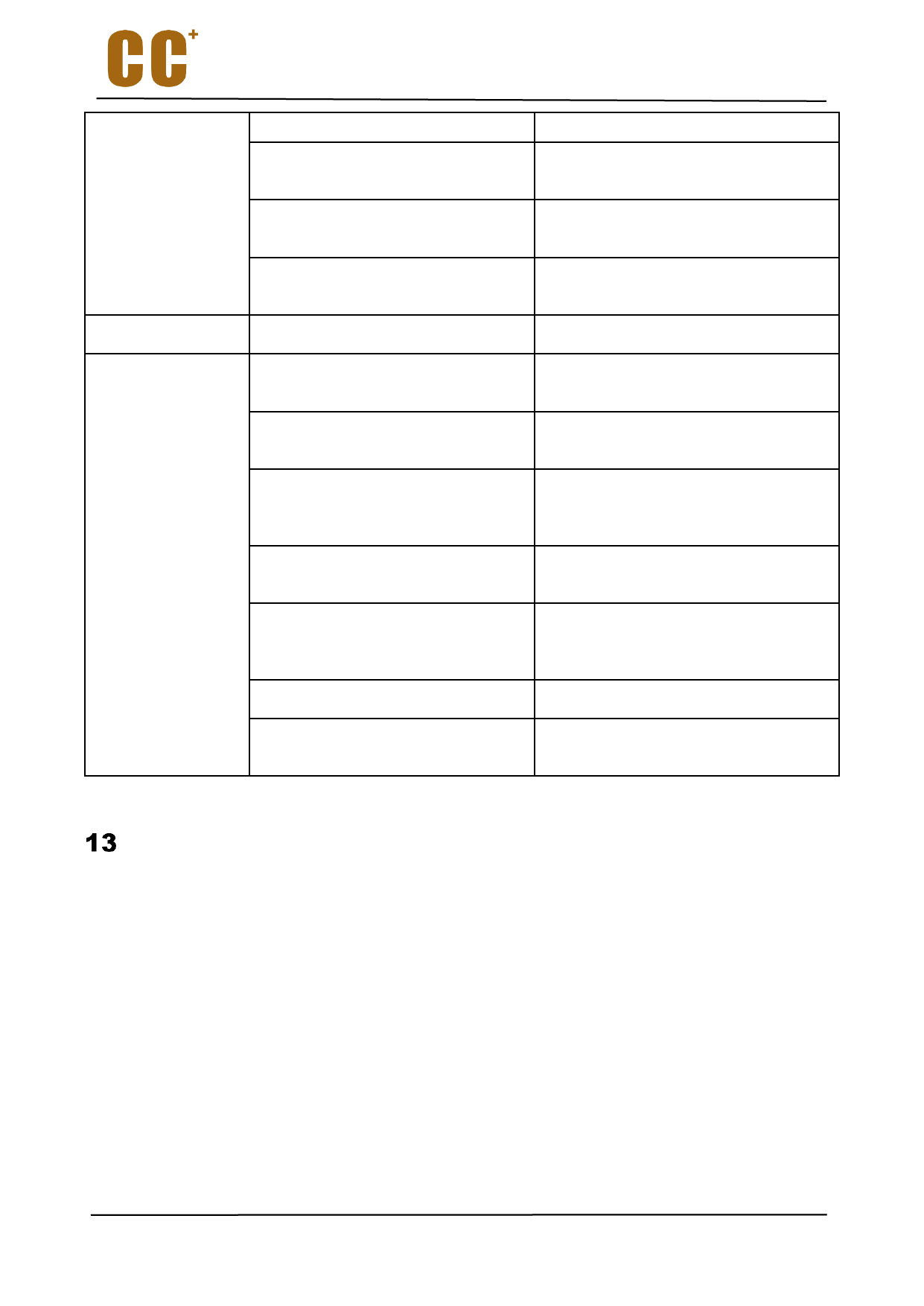

Bearing noise

Electrospindle

vibrations

The machining operation is too

heavy:

Incorrect parameterisation of the

inverter:

Incorrect voltage supply

Bearings damaged

The tool-holder is not balanced:

The tool is not balanced:

Dirt between tool-holder cone and

spindle shaft:

Incorrect parameterization of the

inverter:

The machining operation is too

heavy:

Anchor screws loose:

Incorrect voltage supply

Reassemble the electric fan.

Reduce the severity of the machining

operation.

Check the parameters on the plate of

the electrospindle

Check the voltage of electrospindle on

the plate.

Replace bearings

Choose a tool-holder according to the

indications in above chapters.

Choose and use the tool according to

the indications in in above chapters.

Remove the foreign matter and clean

the tool-holder cone and shaft cone as

described.

Check the parameters on the plate of

the electrospindle.

Reduce the severity of the machining

operation including cutting depth and

feed rate.

Tighten the screws

Check the voltage of electrospindle on

the plate.

DISPOSAL OF SCRAPPED ELECTROSPINDLE

At the end of the electrospindle lifespan, it is the responsibility of the user company to dispose of it.

First of all, the various elements must be cleaned, then the various parts must be separated into

components and electrical material. The different materials should be divided, e.g.: electrical motors

(copper coils), metallic parts, plastic materials etc., and then disposed of separately, according to the

regulations of the current laws in the country of installation.

46