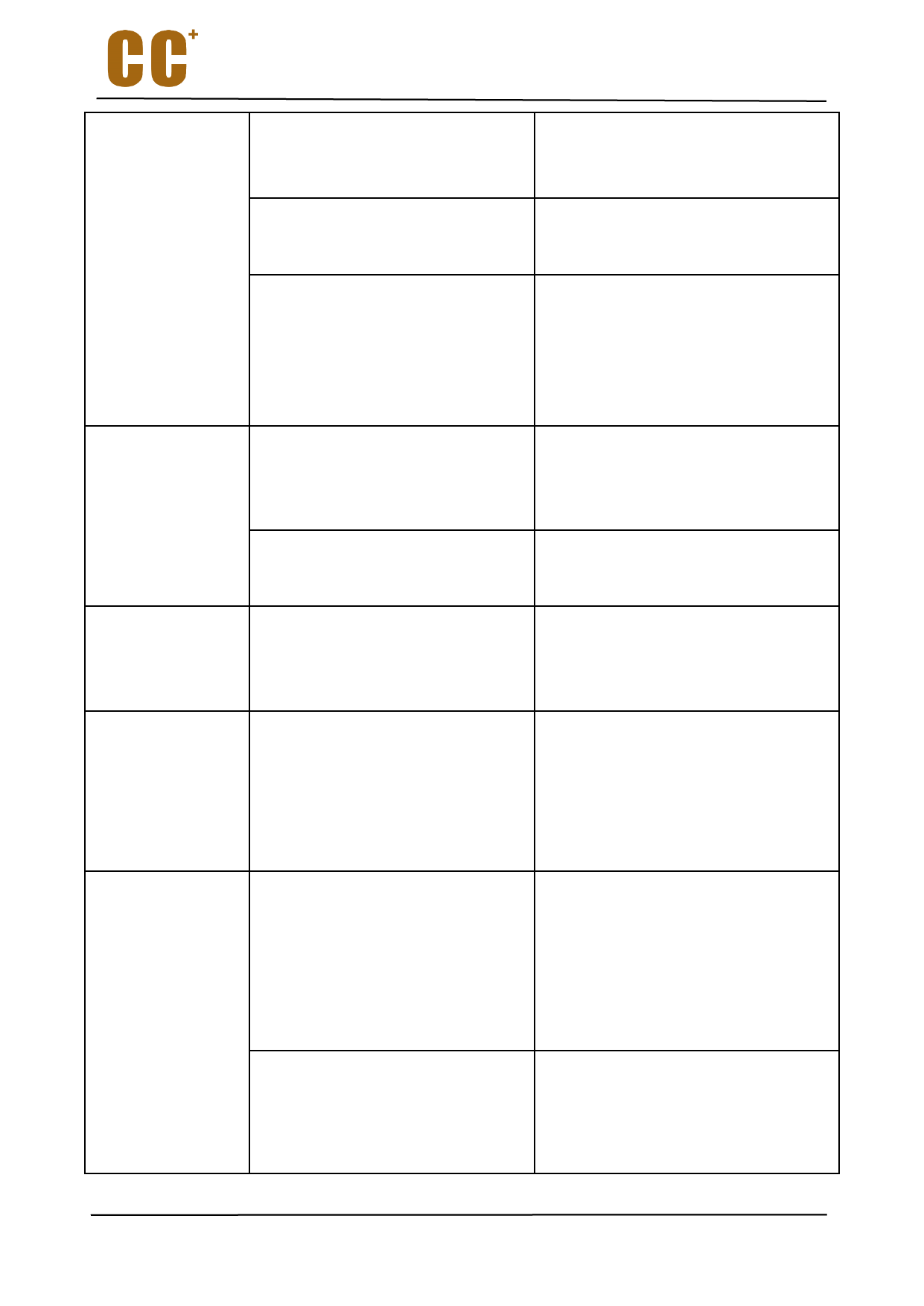

The VFD over-current protection

triggered.

Refer to the VFD's manual or contact

its manufacturers.

No electrospindle start signal

Refer to the manual, or contact the

manufacturers of the machine, digital

controller and VFD.

Sensor S1 disconnected or faulty

Check sensor connector.

Check whether the sensor cable is

broken. Calibrate the sensor

according to the instructions.

Replace any faulty sensors in

accordance with the instructions.

The tool-holder is

not expelled:

Insufficient air pressure

Check the required pressure

values.

Check the integrity and efficiency of

the pneumatic circuit.

No triggered signal

Refer to the manual, or contact the

manufacturers of the machine, digital

controller and VFD.

Lack of

pressurization:

Insufficient pressure or inefficient

pneumatic circuit:

Check the required pressure

values

Check the integrity and efficiency

of the pneumatic circuit;

One of the sensors Sensor disconnected or faulty:

does not provide the

required output:

Check the sensor connection.

Check the integrity and continuity

of the electrical connectors;

Carry out the adjustment of the

sensor as described.

Replace the sensor as described.

The electrospindle The cooling fan is not working

overheats:

properly

Check the electric fan is

operational;

Check the electric fan is integral;

Check that the rotation of the

electric fan is not obstructed by

foreign matter;

Replace the electric fan if it is faulty

The passages where the cooling air

goes through the framework of the

electrospindle are obstructed:

Disassemble the electric fan.

Check and free the passages

where the cooling air goes through

the framework of the

electrospindle;

45