13. At the end of the cycle, check that the condition of the table at point [10] is satisfied. If this is the case,

the adjustment procedure for S1 is completed; if this is not the case, repeat the procedure from the

beginning.

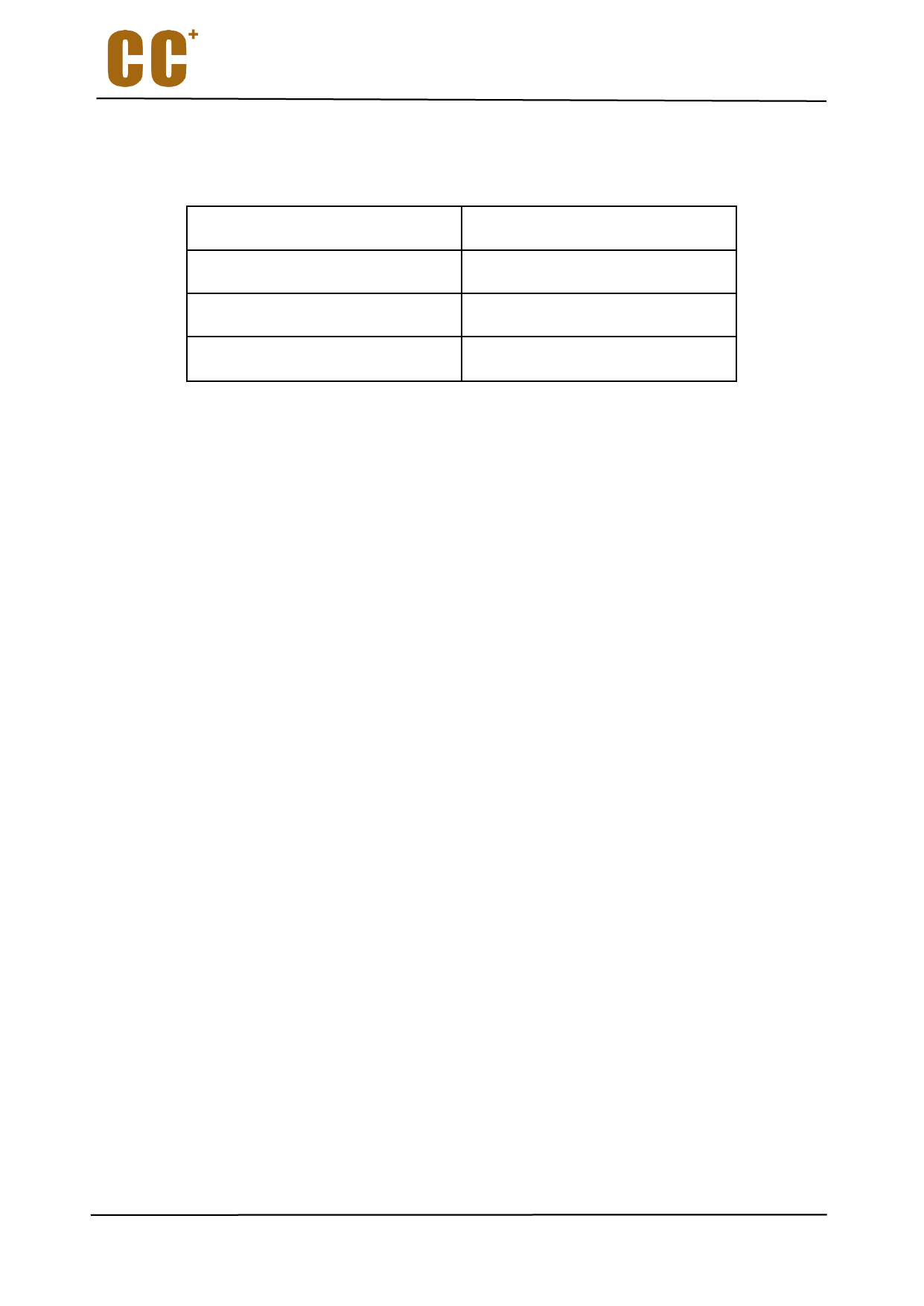

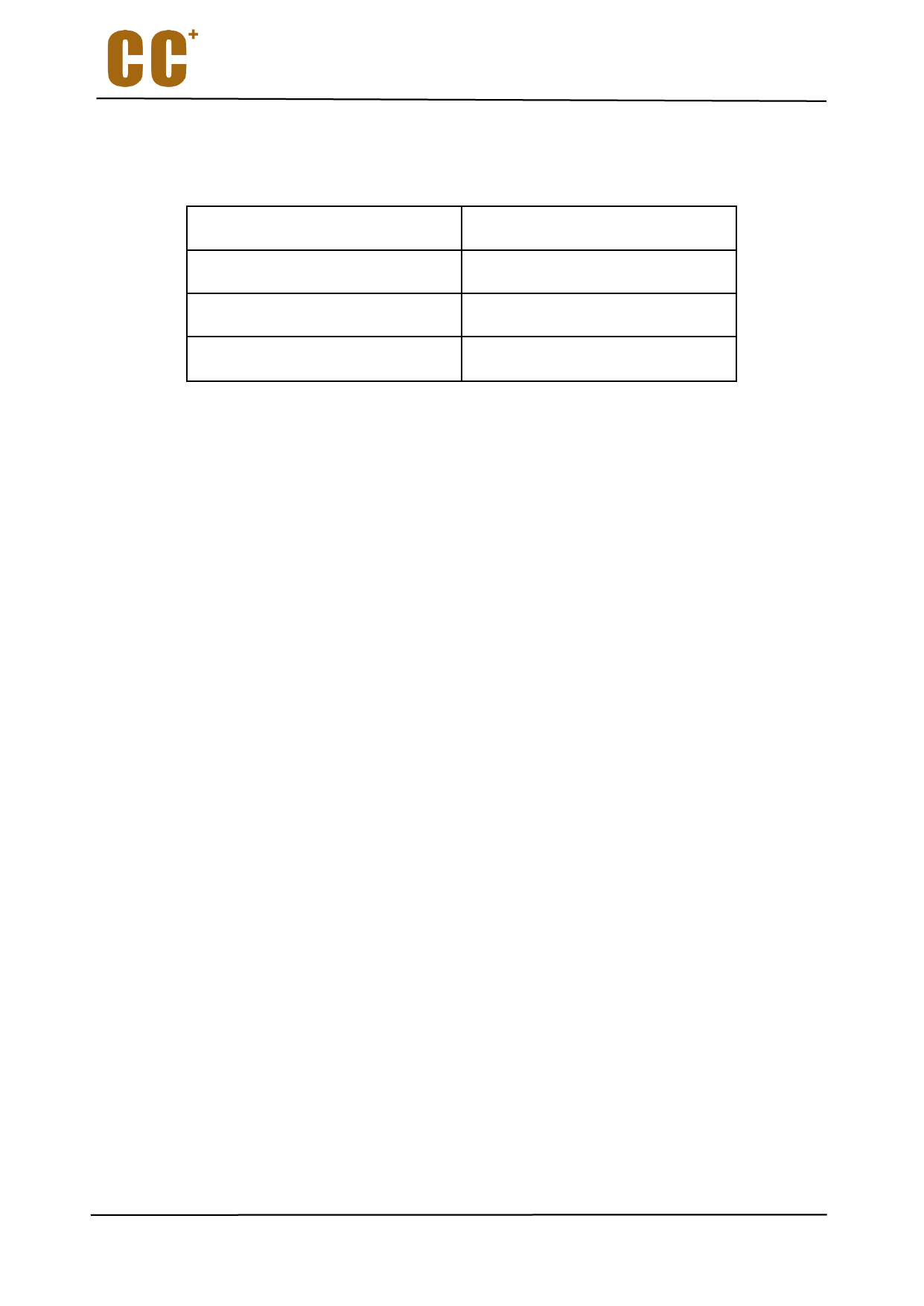

Condition

Output S1

The tool holder locked

十 24V

No tool holder

0V

The tool holder ejected (open collet) 0V

10.2.3.6.2 Calibration for S2

When you have replaced the sensor in accordance with section 10.2.3.5, follow these steps to calibrate.

1. Correctly attach a tool-holder before beginning the adjustment of the sensor;

2. Check that, in this state, the output of S2 is “OFF”; if the output is “ON”, rotate the sensor unit until it

becomes “OFF”;

3. Feed the air input for a tool change of the cylinder, using a one-way pressure regulator initially set at 0

bar;

4. Gradually increase the feed pressure so as to move the piston slowly forward and, at the same time,

check that the output of S2 is “OFF”;

5. As long as the tool-holder is firmly blocked, the output of S2 must be “OFF”; if the output changes during

the movement of the piston, slightly rotate the sensor unit until the output returns to “OFF”;

6. When the tool-holder begins to slacken (but is not yet free to fall), the output of S2 must still be “OFF”

(if necessary, rotate the sensor unit);

7. When you reach the feed pressure at which the tool-holder is finally free to fall, increase the pressure

by another 0.2 bar and block the pressure regulator;

8. Rotate the sensor unit so that, in this state, the output of S2 is “ON”, then fix it by tightening the screw

(3);

9. Perform a cycle of 10 tool changes;

10. At the end of the cycle, check that the steps from [1] to [8] are satisfied, without the need to ever rotate

the sensor;

11. If the outputs requested are not satisfied, repeat the entire procedure from the start;

12. If the outputs requested are satisfied, perform a cycle of 100 tool changes with the machine, using the

maximum possible number of different tool-holders;

13. At the end of the cycle, check that the steps from [1] to [8] are satisfied, without the need to ever rotate

the sensor;

14. If the outputs requested are not satisfied, repeat the entire procedure from the start;

15. If the outputs requested are satisfied, the regulation procedure for S2 is complete.

10.2.3.6.3 Calibration procedure for S3

When you have replaced the sensor in accordance with section 10.2.3.5, follow these steps to calibrate.

1. Check that the signal from the sensor corresponds to that described in the figure below.

40